Innovations & Citations

Recognized for Innovation and Industry Leadership

Over the years, Kahanroba Engineering Company has been recognized for its outstanding contributions to the construction and engineering industries. Our commitment to excellence, innovation, and quality has earned us several prestigious awards and citations. These accolades reflect our unwavering dedication to delivering exceptional results and our ability to consistently exceed industry standards.

We are honored to be recognized by our peers and clients alike, and these awards serve as a testament to the hard work and expertise of our team. At Kahanroba Engineering Company, we remain focused on maintaining the highest standards and continue to strive for excellence in every project we undertake.

Kahanroba Company has solidified its position as a global leader in the processing of non-metallic minerals, with a strong presence in international markets including Turkey, India, Tajikistan, and the United Kingdom. Through cutting-edge research, innovative technologies, and successful industrial projects, we have transformed the mineral processing industry, delivering sustainable and economically viable solutions. Below is a detailed overview of our key achievements:

Revolutionary Zinc Oxide Processing

Kahanroba developed a proprietary method to economically process silicate zinc oxide ores, which are typically laden with impurities like silica, chlorine, and fluorine, rendering them challenging for conventional processing. After extensive laboratory testing and the successful operation of a pilot plant at the Angouran Lead and Zinc Complex (owned by Calcimin Company), we established Iran’s first zinc production facility in 1996. Inaugurated by then-President Hashemi Rafsanjani on April 20, 1996, the plant started with a capacity of 7,000 tons per year, expandable to 14,000 tons. This breakthrough not only localized zinc production technology but also enabled Iran to become self-sufficient in zinc, with installed capacity reaching four times domestic demand. As a result, Iran has emerged as a leading zinc exporter in the region.

Environmental Innovation in SO2 Gas Capture

In collaboration with Novin Engineering Company, Kahanroba designed and implemented a pilot unit to capture sulfur dioxide (SO2) gas emitted from converter furnaces at the Sarcheshmeh Copper Complex. The system achieved an impressive absorption efficiency of 84%, aligning with international standards. By scaling this technology, Kahanroba offers a solution to reduce atmospheric SO2 emissions from power plants and industrial facilities, significantly contributing to environmental sustainability and cleaner air.

Enhanced Lead Production with TBRC Furnace

Originally designed for processing oxidized ores, Kahanroba adapted the TBRC furnace at Iran’s National Lead and Zinc Company to handle sulfide feed through a strategic contract. This adaptation optimized the furnace’s performance, enabling efficient lead production from sulfide ores and showcasing our ability to innovate within existing industrial frameworks.

High-Efficiency Gold Recovery

Kahanroba achieved a significant milestone in gold extraction by developing a heap leaching process in a pilot unit. This method delivered optimal recovery rates for gold ore, demonstrating our expertise in processing precious metals and paving the way for scalable, cost-effective gold recovery solutions.

Advanced Antimony Purification

In Tajikistan, Kahanroba successfully purified antimony concentrate from the Anzob mine, which was contaminated with mercury. Through rigorous research and testing, we not only refined the antimony but also recovered mercury as a valuable byproduct, showcasing our commitment to maximizing resource recovery and minimizing waste

Optimization of Lead Flotation at Lakan Plant

At the Lakan Lead and Zinc Flotation Plant, Kahanroba addressed the challenge of low galena recovery in the lead circuit, where only 50% of galena was recovered, with significant losses to the zinc concentrate. Through targeted research and optimization of reagent use, we significantly improved recovery efficiency, boosting the plant’s overall performance and reducing operational losses.

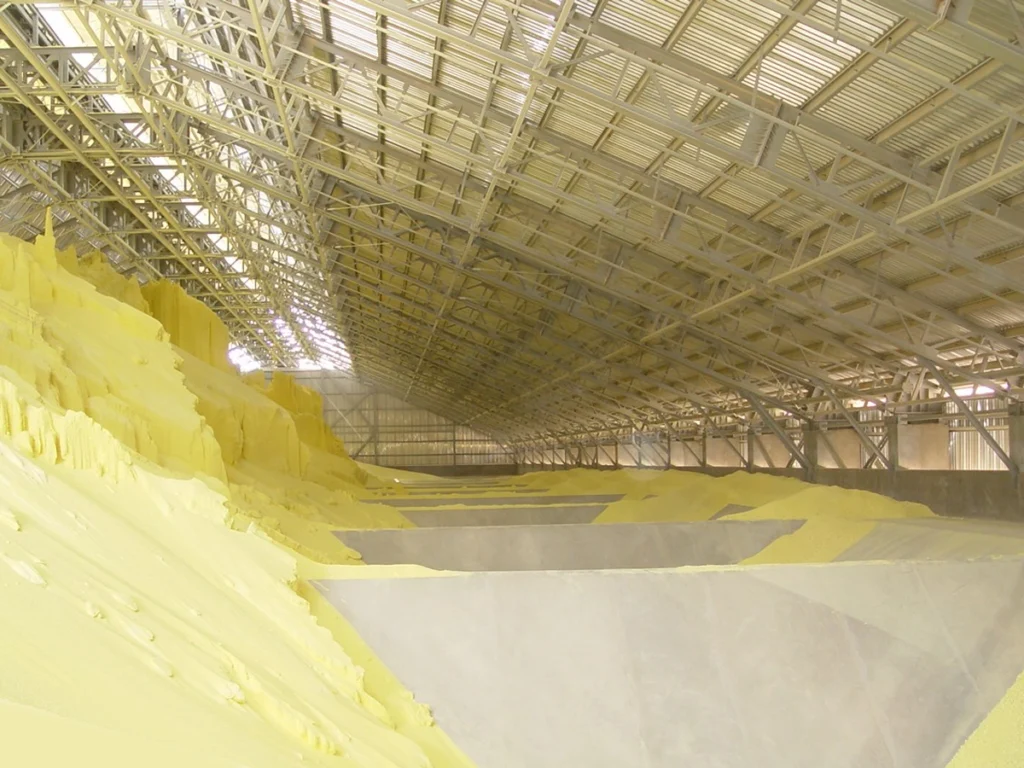

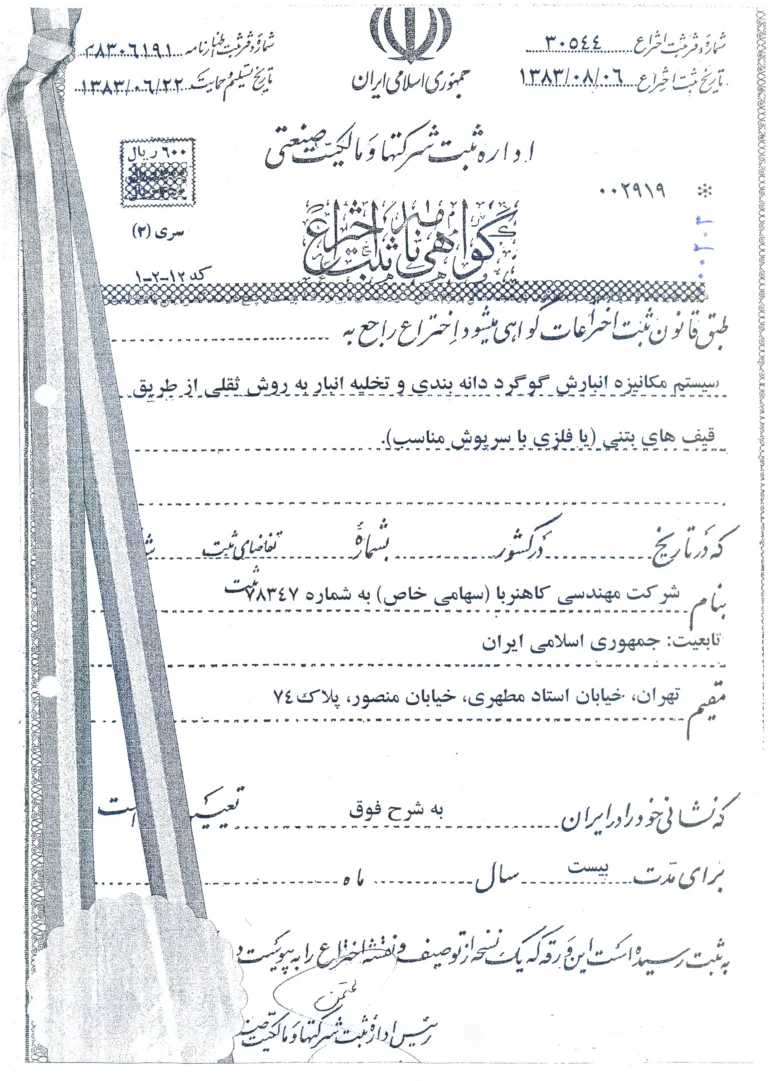

Innovative Sulfur Storage and Handling System

Kahanroba revolutionized sulfur storage by developing a gravity-based discharge system using automated concrete or metal hoppers. Unlike traditional methods that rely on open-air storage or mechanical reclaimers, our system employs a mobile conveyor for top-loading and gravity-fed discharge, minimizing mechanical equipment use. This reduces capital and operational costs, prevents environmental pollution, and avoids sulfur caking—a common issue in sulfur storage. The system, successfully implemented at Kharg Petrochemical Company, allows simultaneous storage and loading without compromising capacity, earning widespread recognition for its efficiency and environmental benefits.